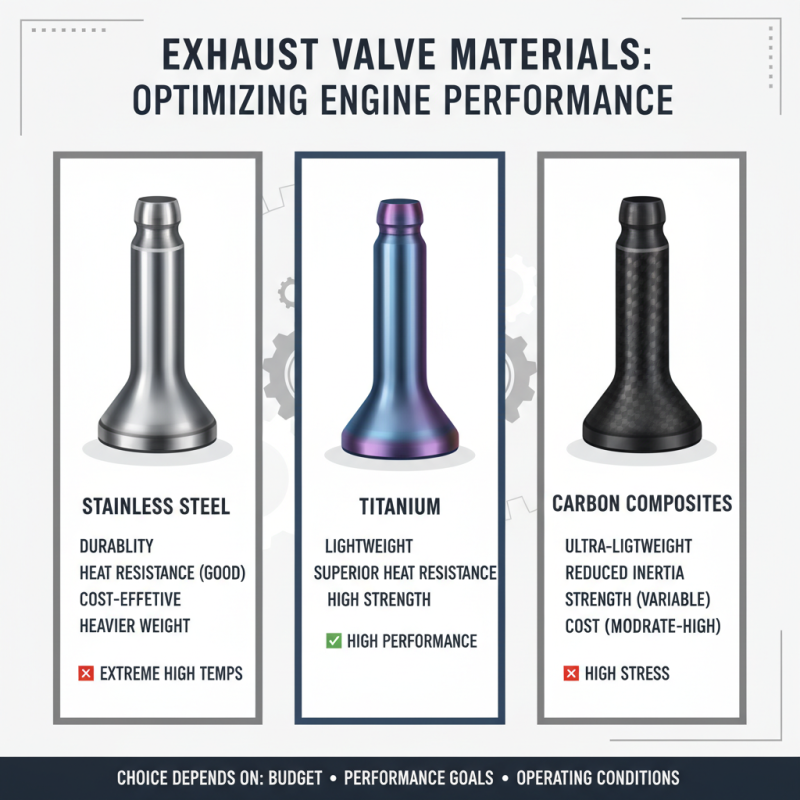

When considering exhaust valves, material selection plays a crucial role in enhancing engine performance. Various materials, such as stainless steel, titanium, and carbon composites, each have their advantages and limitations. Stainless steel is widely used due to its durability and heat resistance. However, it may not perform as well at extremely high temperatures compared to titanium. Titanium valves, while lighter and more heat-resistant, can be more expensive. Composite materials offer lightweight solutions, but may not always provide the same strength under stress.

Tips: Assess your engine's specific needs before choosing a material. Often, the best choice is a compromise between durability and weight.

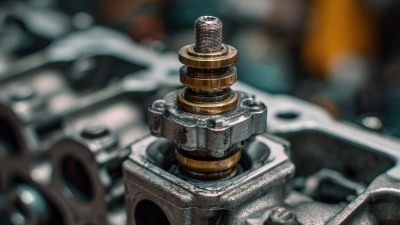

Additionally, the manufacturing process impacts overall valve performance. Forged valves can offer superior strength compared to cast valves. Yet, the latter may be easier to produce at lower costs. This can create trade-offs between performance and affordability that should not be overlooked.

Tips: Always consider the long-term costs associated with performance upgrades. Sometimes, investing more upfront can save money down the road.

Selecting the right exhaust valve requires balancing multiple factors—performance, cost, and engine compatibility. Each option has its unique set of pros and cons. Users must reflect on their priorities and make informed choices accordingly.

+86 17870576410

+86 17870576410

Home

Company Profile

Products

News

Blog

Contact Us

Contact Number

Contact Number