Best Flexible Muffler Pipe Options for 2025 Improved Performance and Durability

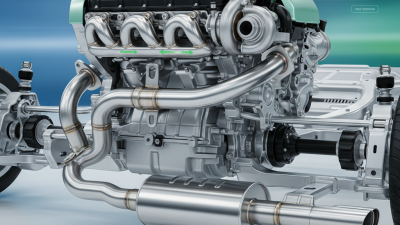

The automotive industry is continuously evolving, pushing the boundaries of performance and efficiency. As we look forward to 2025, one component that stands out in enhancing vehicle capabilities is the Flexible Muffler Pipe. This essential element plays a crucial role in improving exhaust flow, reducing back pressure, and ensuring a smoother operation of the engine. With advancements in materials and manufacturing techniques, the market for flexible muffler pipes has expanded, providing a variety of options that cater to the diverse needs of vehicle enthusiasts and everyday drivers alike.

Flexible Muffler Pipes not only contribute to better engine performance but also enhance the overall durability of the exhaust system. The ability to adapt to engine vibrations and movements allows these pipes to maintain their integrity over time, reducing the risk of leaks or failures. Moreover, with increasing environmental concerns, these pipes are designed to help meet stricter emissions regulations while providing the desired sound characteristics that drivers seek.

In this article, we will explore the best flexible muffler pipe options available in 2025. We will highlight key features, benefits, and considerations to help you choose the right solution for your vehicle, ensuring an optimal balance of performance and longevity. From innovative designs to advanced materials, the future of flexible muffler pipes promises exciting improvements for any car or truck owner looking to upgrade their exhaust system.

Best Flexible Muffler Pipe Materials for Enhanced Performance

When considering flexible muffler pipes, the choice of material is crucial for enhanced performance and durability. One of the top contenders is stainless steel, known for its corrosion resistance and ability to withstand high temperatures. This material not only prolongs the life of the muffler pipe but also contributes to an efficient exhaust flow, resulting in improved engine performance. Additionally, stainless steel offers a sleek appearance, making it a popular choice among automotive enthusiasts.

Another noteworthy material is aluminized steel, which is treated to resist rust and oxidation. While it might not be as durable as stainless steel, it provides a cost-effective option for those seeking enhanced performance without breaking the bank. Aluminized steel is lightweight, which can also contribute to a slight reduction in overall vehicle weight, potentially improving acceleration and fuel efficiency. This makes it an excellent choice for everyday drivers looking for an upgrade to their exhaust system.

Furthermore, advanced composite materials are emerging as viable options for flexible muffler pipes. These composites can combine lightweight properties with exceptional heat resistance, offering a high-tech solution to traditional materials. As technology continues to evolve, these innovative materials hold promise for future applications, allowing performance-driven drivers to experience both improved exhaust flow and reduced weight in their vehicles.

Key Features to Consider When Choosing Flexible Muffler Pipes

When selecting flexible muffler pipes for optimal performance and durability, several key features should be closely examined. First, the material used in the construction of the pipe is crucial. Look for high-quality stainless steel or aluminized steel, as these materials not only resist rust and corrosion but also withstand high temperatures. Additionally, the construction process matters; mandrel-bent pipes provide a smoother flow due to their seamless design, which can significantly enhance exhaust flow and performance.

Another important factor to consider is the diameter of the pipe. A properly sized pipe will ensure a balance between back pressure and exhaust flow, leading to improved engine efficiency. Furthermore, the flexibility of the pipe is essential for easy installation and to accommodate engine vibrations without compromising the structural integrity of the exhaust system. Finally, consider the design features such as welded joints and reinforced ends, which can contribute to the longevity and reliability of the muffler pipe, ensuring it can handle the rigors of various driving conditions.

Best Flexible Muffler Pipe Options for 2025 - Improved Performance and Durability

| Model |

Material |

Length (inches) |

Inner Diameter (inches) |

Max Temperature (°F) |

Warranty (Years) |

| FlexiPipe Pro |

Stainless Steel |

24 |

2.5 |

1200 |

3 |

| UltraFlex 2000 |

Aluminized Steel |

30 |

3.0 |

1000 |

2 |

| FlexBoost 360 |

Carbon Steel |

36 |

2.75 |

1100 |

5 |

| MufflerMax Flex |

Stainless Steel |

28 |

2.5 |

1250 |

4 |

| Resilient Flex |

Aluminized Steel |

32 |

3.0 |

1050 |

3 |

Top Brands Offering Flexible Muffler Pipes for 2025

In the realm of automotive performance, the demand for

high-quality flexible muffler pipes has surged as enthusiasts seek to enhance their vehicle's efficiency and sound quality. As we look towards 2025, several manufacturers are leading the charge in innovation, offering products that emphasize improved durability and functionality. These companies are developing flexible muffler pipes that not only conform to the needs of various vehicle designs but also withstand the rigors of daily use, including extreme temperatures and corrosive environments.

Top brands are integrating advanced materials and manufacturing techniques into their designs, ensuring that their flexible muffler pipes can endure wear while maintaining optimal performance. These pipes are being crafted for seamless installation and adaptability, providing options that cater to a wide array of vehicles, from compact cars to full-sized trucks. Additionally, these brands are focusing on enhancing the acoustic properties of their products, allowing for a smoother, more refined exhaust note that meets the preferences of discerning drivers.

As 2025 approaches, the market is poised to offer a range of flexible muffler pipes that combine innovation with performance, setting a higher standard in the automotive aftermarket.

Comparison of Flexible Muffler Pipe Designs for Durability

When considering flexible muffler pipe designs for enhanced durability, it is essential to evaluate materials and construction methods. High-quality stainless steel and advanced polymer composites are at the forefront of modern muffler technology, providing superior resistance to rust and corrosion. These materials not only withstand high temperatures but also adapt well to the vibrations and stresses associated with vehicle operation. The innovative designs incorporate features such as reinforced seams and adjustable joints, which contribute to a longer lifespan and optimized performance under varying conditions.

In addition to materials, the design and manufacturing processes play a crucial role in the durability of flexible muffler pipes. Many manufacturers are now employing advanced welding techniques and precision engineering to ensure structural integrity. Moreover, the introduction of innovative features like noise reduction chambers and enhanced flow passages can further improve performance while maintaining resilience. As the automotive industry continues to evolve, focusing on these aspects of muffler pipe design is vital for consumers looking to invest in reliable and long-lasting exhaust solutions.

Installation Tips for Optimal Use of Flexible Muffler Pipes

When considering the installation of flexible muffler pipes, it’s essential to follow best practices to ensure optimal performance and longevity. A professional report from the Automotive Exhaust Systems Association indicates that up to 20% of exhaust-related issues stem from improper installations. Therefore, prioritizing correct installation techniques can significantly enhance the durability and efficiency of your muffler system.

Before embarking on the installation, make sure to thoroughly inspect all components for any signs of wear or damage. Ideally, the installation should take place in a well-ventilated area, using proper jacks and stands to ensure safety. It's recommended to use high-temperature resistant materials for connections, as studies show that this approach can extend the lifespan of exhaust systems by as much as 30%. Additionally, maintaining proper alignment during installation will help reduce stress on joints, which commonly leads to premature failure.

One tip to keep in mind is to always use the right tools for securing flexible muffler pipes. Using tools like a torque wrench can help maintain the correct tension on bolts, preventing any leaks that could affect engine performance. Another important aspect is ensuring sufficient clearance between the pipe and nearby components to avoid heat damage. Following these tips will not only optimize the system's performance but also provide peace of mind about its longevity under various driving conditions.

+86 17870576410

+86 17870576410

Home

Company Profile

Products

News

Blog

Contact Us

Contact Number

Contact Number