2026 How to Choose Flexible Exhaust Tubing for Your Vehicle?

Choosing the right flexible exhaust tubing for your vehicle can significantly impact performance. This decision is crucial for optimizing exhaust flow. It also directly influences sound and efficiency.

Flexible exhaust tubing offers versatility. It can fit various tight spaces, especially in modified vehicles. However, not all tubing is created equal. Material quality and size are essential factors to consider. Poor choices may lead to leaks or exhaust noise, which can be frustrating.

Investing in durable flexible exhaust tubing is wise. It can withstand high temperatures and harsh conditions. Yet, many overlook installation intricacies. Improper installation might lead to issues down the road. Thus, assessing your vehicle's specific needs is vital. Each choice matters, so think critically about what suits your situation best.

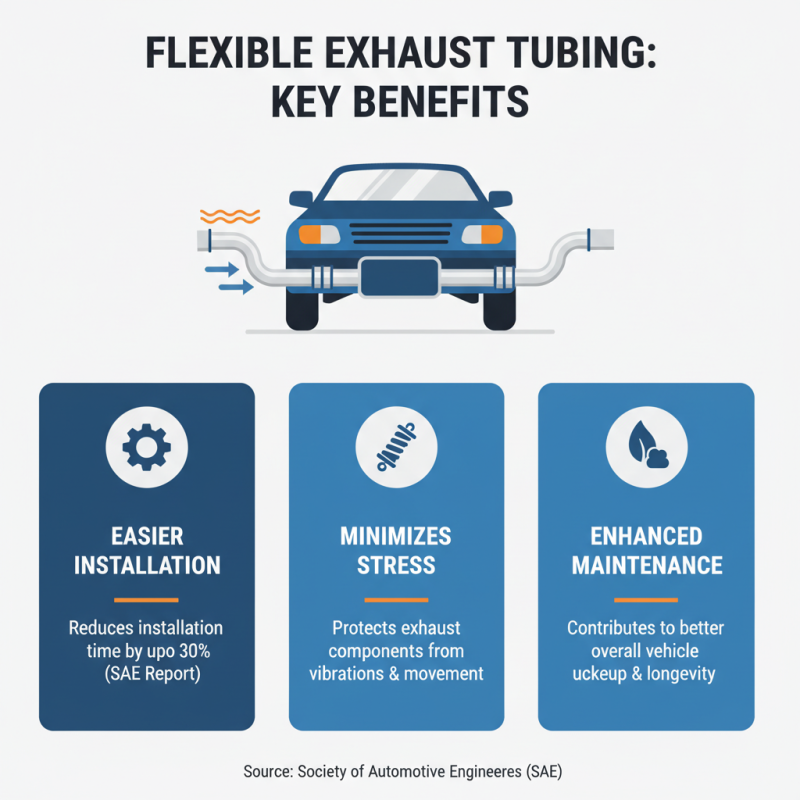

Understanding the Importance of Flexible Exhaust Tubing

Flexible exhaust tubing plays a crucial role in vehicle performance and emissions control. It allows for easier installation and adjustments, minimizing stress on exhaust components. According to a report by the Society of Automotive Engineers, flexible tubing can reduce installation time by up to 30%. This efficiency can greatly enhance the overall maintenance of a vehicle.

Understanding the importance of flexible exhaust tubing also means recognizing its impact on vehicle longevity. Poor quality or improperly installed tubing can lead to exhaust leaks. Such leaks negatively affect engine performance and can increase harmful emissions by 10% or more. Choosing the right tubing involves considering materials that resist corrosion and withstand extreme temperatures. Common materials include stainless steel and silicone-based options, each offering unique benefits.

However, flexibility comes with its challenges. Some materials may become brittle over time. This brittleness can lead to potential failures. Not all flexible tubing meets industry standards. It is essential to evaluate certifications and performance ratings. Investing in quality can prevent costly repairs down the road.

Types of Flexible Exhaust Tubing Available for Vehicles

When choosing flexible exhaust tubing, understanding the types available is crucial. There are generally three main types:

stainless steel, aluminized steel, and rubber.

Stainless steel tubing is durable and resistant to corrosion. It can withstand extreme temperatures. However, it tends to be pricier than alternatives.

Aluminized steel is less expensive but may not last as long, especially in harsh conditions.

Rubber tubing offers flexibility for easy installation. It can absorb vibrations effectively. But it might not endure high heat situations well.

According to industry reports, rubber is often the choice for temporary fixes. Data indicates that about 40% of vehicle owners replace their exhaust tubing every few years.

Material selection matters significantly. Stainless steel may have a lifespan of over 20 years, while rubber typically lasts around 5 years.

Many users overlook maintenance needs as well. Regular checks can prevent exhaust leaks.

Ensuring the right type can save money on repairs later.

It’s essential to weigh costs versus longevity when making a decision.

Factors to Consider When Choosing Flexible Exhaust Tubing

When choosing flexible exhaust tubing, several factors come into play. One of the primary considerations is the material.

Stainless steel is popular due to its corrosion resistance and longevity. Reports indicate that vehicles with stainless steel tubing have a

20% longer lifespan than those with other materials. However, mild steel is often cheaper but may rust quickly if not coated.

Another factor is the tubing diameter. The diameter directly impacts exhaust flow. A diameter that is too small can restrict airflow, negatively affecting engine performance.

Studies show that an optimal diameter can improve horsepower by 5-10%. Additionally, consider the temperature resistance of the tubing.

Exhaust temperatures can exceed 1,500°F, making it crucial to select tubing that can withstand high heat without deforming.

Installation ease should not be overlooked. Flexible tubing is designed for quick installation in tight spaces. However, some users report challenges with securing them properly.

This can lead to leaks or rattling noises. It’s essential to balance flexibility with secure fittings to avoid these issues. Choosing the right flexible exhaust tubing involves

careful consideration of materials, diameter, and installation methods.

Installation Tips for Flexible Exhaust Tubing

When installing flexible exhaust tubing, preparation is key. Ensure you have the right tools on hand: a saw, clamps, and possibly a wrench. Clean the area where you'll be working. Dust, grease, or old residues can cause issues during installation. Take your time to inspect the existing exhaust system. Look for any damages or rust that might affect the new tubing.

Cut the flexible tubing to the required length. It should fit snugly in place, neither too tight nor too loose. Use clamps to secure connections, but avoid overtightening. This can lead to cracks over time. If you’re unsure about your alignment, it may help to double-check. Sometimes, things might seem aligned but are not.

After installation, start your vehicle and listen for unusual sounds. A leak might be present if you hear any hissing or loud noises. Additionally, check for potential vibrations; these could indicate that the tubing isn't anchored properly. Reflect on your process. Did you miss any steps? Were there moments that caused confusion? These reflections can improve your skills for future projects.

2026 How to Choose Flexible Exhaust Tubing for Your Vehicle? - Installation Tips for Flexible Exhaust Tubing

| Dimension |

Material |

Temperature Resistance |

Diameter Options |

Recommended Use |

Installation Tips |

| 1.5 inches |

Stainless Steel |

Up to 1200°F |

1.5" to 3" |

Performance Exhausts |

Ensure tight clamps are used. |

| 2 inches |

Aluminized Steel |

Up to 800°F |

2" to 4" |

General Replacement |

Use anti-seize on threads. |

| 3 inches |

Flexible PVC |

Up to 650°F |

3" to 5" |

Custom Applications |

Check for kinks during installation. |

| 4 inches |

T304 Stainless Steel |

Up to 1300°F |

4" to 6" |

High-Performance Racing |

Ensure proper alignment before tightening. |

Maintaining Flexible Exhaust Tubing for Optimal Performance

Maintaining flexible exhaust tubing is crucial for your vehicle's performance. Over time, these tubes can experience wear and tear. Regular inspections can help you catch issues early. Look for cracks, holes, or loose connections. Such problems can lead to exhaust leaks, which affect engine efficiency.

Cleaning the tubing is essential. Dirt and debris can build up inside. This buildup restricts airflow and reduces performance. Consider using a mild cleaning solution. A soft brush can help remove stubborn grime. However, be cautious. Aggressive cleaning can damage the tubing's surface.

Additionally, monitor the tubing's positioning. Misalignment can cause early wear. Ensure that it remains properly secured and does not touch other components. Some adjustments may be necessary from time to time. Ignoring these details might lead to more complex issues later. Remember, keeping a close eye on your flexible exhaust tubing can make a significant difference.

2026 Flexible Exhaust Tubing Performance Analysis

+86 17870576410

+86 17870576410

Home

Company Profile

Products

News

Blog

Contact Us

Contact Number

Contact Number