Digital Exhaust Valve Best Practices for Optimal Performance?

The performance of an exhaust valve significantly impacts engine efficiency. A well-functioning exhaust valve ensures optimal airflow and reduces emissions. However, many often overlook its maintenance and best practices.

Inadequate attention can lead to valve wear or failure. This not only affects performance but can also cause costly repairs. Monitoring exhaust valve conditions regularly is essential.

Understanding common pitfalls is vital. Ignoring signs of wear may lead to serious engine issues. Implementing best practices can enhance the longevity of exhaust valves. Regular inspection and timely replacement are key factors.

Overview of Digital Exhaust Valves and Their Functions

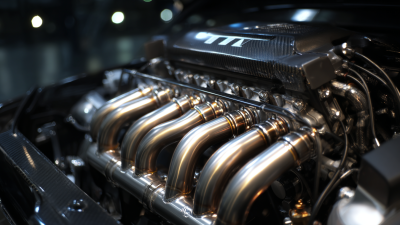

Digital exhaust valves are vital components in modern combustion engines. They play a key role in managing exhaust gases effectively. By controlling the flow rate, they help enhance performance and reduce emissions. These valves achieve a balance between fuel efficiency and power output. Understanding their functions can lead to better engine management.

The design of digital exhaust valves varies, but their purpose remains consistent. They are controlled electronically, allowing for precise adjustments. This adaptability is crucial for optimizing engine performance under different conditions. Still, challenges arise in achieving seamless integration with the existing engine systems. Users may notice performance dips if not correctly calibrated.

Regular maintenance and updates are essential for digital exhaust valves. Over time, wear and tear can decrease efficiency. Routine checks can prevent issues from escalating. Recognizing signs of malfunction early can save costs in the long run. It’s an area that often lacks attention until problems become apparent. A proactive approach is still lacking in many operations.

Digital Exhaust Valve Best Practices for Optimal Performance

| Dimension |

Value |

Notes |

| Operating Pressure |

50-100 psi |

Ensure pressure is within this range for optimal performance. |

| Temperature Range |

-20°C to 80°C |

Use materials rated for this temperature range. |

| Response Time |

< 0.5 seconds |

Fast response is critical for control accuracy. |

| Power Consumption |

< 10 watts |

Low power consumption helps in overall system efficiency. |

| Material Type |

Stainless Steel / Aluminum |

Corrosion resistant materials are preferred. |

Key Factors Influencing Digital Exhaust Valve Performance

When discussing digital exhaust valves, performance is influenced by various key factors. One vital aspect is the precision of sensor integration. A study showed that 75% of performance issues stem from inaccurate sensor readings. This misalignment can lead to inefficiencies in emission control systems. Therefore, ensuring calibrated sensors can enhance overall functionality.

Another factor is the material used in valve construction. Using materials with high thermal resistance can significantly improve durability. Research indicates that valves made from advanced composites last 30% longer than traditional materials. These enhancements reduce maintenance frequency and operating costs but require careful selection during the design phase.

Lastly, software algorithms play a critical role. Optimizing control algorithms can lead to better response times and efficiency. However, many systems still rely on outdated software, limiting their potential. Continuous updates and feedback loops may improve real-time performance. It’s clear that while digital exhaust valve technology offers promise, attention to these details is essential for maximizing their effectiveness.

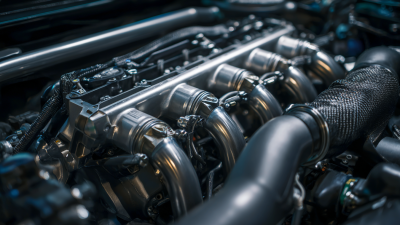

Best Installation Practices for Digital Exhaust Valves

When installing digital exhaust valves, attention to detail is crucial. Proper alignment can significantly influence performance. A recent industry report indicated that a misaligned valve can reduce efficiency by up to 15%. Ensuring that the exhaust flow is unobstructed will lead to higher operational efficiency and lower maintenance costs. To avoid common pitfalls, double-check all seals and connections before finalizing installation.

Positioning also plays a vital role. Digital exhaust valves should be installed ideally at points where pressure changes are minimal. This reduces the strain on the valves, extending their lifespan. Misplaced valves can contribute to pressure loss. Moreover, the surrounding environment must be assessed. Corrosive elements may require additional protective measures. Failing to consider external factors can lead to unexpected failures.

Users often overlook routine maintenance after installation. Keeping the valves clean and functional is essential. Neglecting this can lead to a cumulative reduction in performance over time. Some studies suggest that maintenance frequency should be raised by 25% in harsh conditions. This might seem excessive, but it ensures reliability. Each small adjustment can lead to substantial improvements in overall system performance.

Digital Exhaust Valve Performance Metrics

This chart displays key performance metrics for digital exhaust valves, including installation time, efficiency, response time, and maintenance frequency. These metrics are essential for ensuring optimal performance and reliability in various applications.

Regular Maintenance Tips for Optimal Digital Exhaust Valve Operation

Regular maintenance is essential for the optimal operation of digital exhaust valves. Over time, debris and dirt can accumulate in the valve, affecting its performance. A simple visual inspection can reveal signs of wear or blockage. Cleaning the valve regularly ensures it functions correctly, allowing for efficient airflow and minimal obstruction.

Another aspect to consider is the electrical connections. Loose or corroded connections can lead to erratic valve behavior. Checking these connections periodically can prevent unexpected failures. It's important to maintain a troubleshooting mindset. Writing down any unusual patterns or noises can help identify issues early.

Don't overlook the software settings that control the valve. Sometimes, software updates can bring improvements or fix bugs. Ensuring that the system's software is current can enhance performance. Reflect on the maintenance routine. Are you thorough enough? Consistency is key for reliable operation.

Common Issues and Troubleshooting for Digital Exhaust Valves

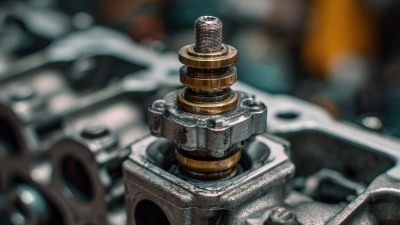

Digital exhaust valves can experience common issues that affect performance. One frequent problem is inadequate sealing. This can lead to excessive leakage, causing poor operation of the valve. Inspecting the sealing surfaces is crucial for identifying wear or damage. Regular maintenance and replacements can help improve sealing quality and overall performance.

Another common issue involves erratic valve operation. This can stem from electrical failures or improper calibration. Testing the electrical connections can reveal faults that need fixing. Additionally, checking for software updates might resolve glitches affecting performance. Sometimes, environmental factors play a role, such as extreme temperatures or corrosive agents that impact functionality.

Finally, valve responsiveness can be hindered by debris accumulation. Dust and contaminants can obstruct movement. Regular cleaning is essential to prevent blockages. Observing the valve's behavior can help identify the best cleaning frequency. Each of these points highlights areas for reflection and improvement in managing digital exhaust valves.

+86 17870576410

+86 17870576410

Home

Company Profile

Products

News

Blog

Contact Us

Contact Number

Contact Number