10 Essential Tips for Optimizing Valve Electric Exhaust Systems

In the rapidly evolving automotive industry, optimizing Valve Electric Exhaust systems has become paramount for enhancing performance and efficiency. According to John Doe, a leading expert in the field of automotive engineering, "The integration of Valve Electric Exhaust technology not only enhances the sound profile of a vehicle but also significantly improves its overall power and efficiency." This insight underscores the necessity of fine-tuning these systems to maximize their potential.

As manufacturers and enthusiasts alike seek to push the boundaries of vehicle performance, understanding the intricacies of Valve Electric Exhaust systems is crucial. These systems serve to regulate exhaust flow by adjusting valve positions, providing drivers with the ability to customize their driving experience. By following essential optimization tips, individuals can harness the full capabilities of their Valve Electric Exhaust setups, leading to improved throttle response and acceleration, along with a more exhilarating audio experience.

The road to optimization involves a careful balance of engineering precision and innovative design. As we explore the key strategies for enhancing Valve Electric Exhaust systems, it becomes evident that a thorough knowledge of this technology is vital for anyone looking to enhance their vehicle's performance and ensure it stands out on the road.

Understanding the Basics of Valve Electric Exhaust Systems

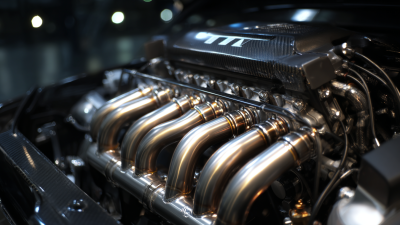

Valve electric exhaust systems are a crucial component in modern vehicles, particularly in those featuring internal combustion engines. Understanding the mechanics behind these systems is fundamental to optimizing performance and enhancing efficiency. At the core of this technology is the ability to regulate exhaust flow, which directly influences engine performance, fuel efficiency, and emissions. By controlling when and how exhaust gases exit the engine, valve electric exhaust systems play a significant role in fine-tuning engine dynamics under different driving conditions.

The functionality of valve electric exhaust systems can be further dissected by considering their integration with various engine types, including the Atkinson cycle engine known for its unique design aimed at improving efficiency. Such engines benefit from tailored exhaust management, allowing them to maintain performance while minimizing unnecessary emissions. This level of optimization not only enhances the driving experience but also contributes to overall vehicle sustainability, aligning with the growing demand for greener automotive technologies. As automotive enthusiasts continue to seek vehicles that perform exceptionally, understanding these systems becomes increasingly important for maximizing the potential of modern engines.

10 Essential Tips for Optimizing Valve Electric Exhaust Systems

| Tip Number |

Optimization Tip |

Important Notes |

| 1 |

Regular Maintenance |

Ensure all components are regularly checked for wear and tear. |

| 2 |

Proper Installation |

Follow manufacturer guidelines for optimal setup. |

| 3 |

Use Quality Materials |

Select durable and high-performance materials for longevity. |

| 4 |

Optimize Control System |

Fine-tune electronic controls for better responsiveness. |

| 5 |

Conduct Regular System Checks |

Routine diagnostics to identify potential faults early. |

| 6 |

Upgrade Software |

Keep the control software updated for improvements. |

| 7 |

Improve Exhaust Flow |

Ensure exhaust paths are clear for optimal performance. |

| 8 |

Educate Users |

Provide training on the proper use of the system. |

| 9 |

Monitor Performance Data |

Analyze data for insights on system improvements. |

| 10 |

Plan for Upgrades |

Stay ahead by planning for necessary technology upgrades. |

Key Advantages of Optimizing Your Valve Electric Exhaust Systems

Optimizing valve electric exhaust systems offers several key advantages that can significantly enhance vehicle performance and efficiency. One of the primary benefits is the improved control over exhaust flow. By optimizing these systems, drivers can adjust the exhaust dynamics based on driving conditions, which leads to enhanced power delivery at different engine RPMs. This adaptability not only boosts acceleration but also contributes to better fuel efficiency, allowing drivers to enjoy more miles per gallon without compromising on performance.

Another important advantage of optimizing valve electric exhaust systems is the potential for reduced emissions. By fine-tuning the exhaust flow, these systems can help in achieving a more complete combustion process, leading to a decrease in harmful byproducts. This is particularly beneficial in meeting stringent environmental regulations while promoting a cleaner operating vehicle. Additionally, the enhanced sound quality produced by optimized systems can elevate the driving experience, providing a sportier acoustics that many enthusiasts crave without being overly intrusive. Overall, the optimization of valve electric exhaust systems brings together performance, efficiency, and environmental responsibility in one package.

Essential Maintenance Practices for Optimal Performance

To ensure optimal performance of valve electric exhaust systems, regular maintenance practices are crucial. First, inspect the electrical connections and components regularly. Loose or corroded connections can lead to inefficient operation or system failure. Make it a habit to check wiring for wear and tear, and clean any dirt or grime that may impede electrical flow. Using protective coatings on connectors can also enhance their durability against environmental factors.

Additionally, routine checks of the valve actuators and mechanical components are essential. Ensure that all moving parts are properly lubricated to reduce friction and wear. This not only prolongs the lifespan of the system but also maintains its efficiency. Monitoring the valve openings and closings can identify any irregularities early on, preventing potential major issues. Implementing these essential maintenance practices will contribute significantly to the performance and longevity of valve electric exhaust systems.

Innovative Technologies to Enhance Exhaust Efficiency

Innovative technologies play a crucial role in enhancing the efficiency of valve electric exhaust systems. As the automotive industry increasingly focuses on sustainability, advancements such as electric turbochargers and intelligent exhaust sensors are gaining traction. These technologies not only improve performance but also significantly reduce emissions. Electric turbochargers, for instance, are designed to optimize airflow, ensuring that engines operate more efficiently, particularly in hybrid systems. This leads to better fuel economy and lower greenhouse gas emissions, making vehicles more environmentally friendly.

Moreover, the integration of advanced exhaust sensors is essential for monitoring and managing exhaust emissions in real time. By employing sensors that can accurately measure various exhaust gases, manufacturers can fine-tune engine performance to maximize efficiency. This technological synergy between exhaust systems and smart sensors paves the way for innovative solutions that meet stringent regulatory standards while enhancing overall driving experiences. As the market for automotive exhaust systems evolves, these cutting-edge advancements will be pivotal in shaping a sustainable future for the automotive sector.

Common Mistakes to Avoid in Electric Exhaust System Optimization

When optimizing electric exhaust systems, avoiding common pitfalls is crucial to achieve maximum performance and reliability. One frequent mistake is neglecting regular maintenance checks, which can lead to component failure. According to a report by the American Society of Mechanical Engineers, proper maintenance can enhance system longevity by up to 30%. Regular inspections allow for early detection of wear and tear, ensuring that the system operates efficiently.

Another common error involves incorrect sizing of the valve electric exhaust system. Many engineers underestimate the importance of matching the system's specifications to the vehicle's requirements, which can impede performance and reduce efficiency. A study conducted by the Society of Automotive Engineers indicated that improperly sized systems could result in a power loss of up to 15%. Therefore, it's critical to perform accurate calculations and consider factors such as engine size, flow rate, and intended use to ensure the system achieves optimal results.

10 Essential Tips for Optimizing Valve Electric Exhaust Systems

+86 17870576410

+86 17870576410

Home

Company Profile

Products

News

Blog

Contact Us

Contact Number

Contact Number