Ultimate Guide to Exhaust Pipe Flange Types and Applications in 2025

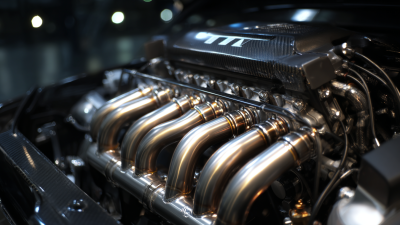

In the ever-evolving landscape of automotive engineering, understanding the various types and applications of exhaust pipe flanges has become crucial for professionals in the industry. As we approach 2025, advancements in technology and material science are shaping the design and functionality of these components. Renowned exhaust systems expert, Dr. James L. Carter, emphasizes the significance of this topic: "The choice of exhaust pipe flange can determine not only the performance but also the longevity of the exhaust system."

With the proliferation of alternative fuel vehicles and stricter emission regulations, the demand for efficient exhaust solutions has skyrocketed. Exhaust pipe flanges play a pivotal role in ensuring optimal sealing and fitment within the exhaust system. Whether focusing on standard flanges for traditional combustion engines or custom designs for electric and hybrid vehicles, comprehending the nuances of exhaust pipe flange types and their specific applications is essential for engineers, manufacturers, and automotive enthusiasts alike.

This ultimate guide will delve into the different varieties of exhaust pipe flanges available, their corresponding applications, and emerging trends that could redefine the industry in the coming years. By equipping readers with a comprehensive understanding of exhaust pipe flanges, we aim to prepare them for the challenges and innovations that lie ahead in automotive exhaust system design.

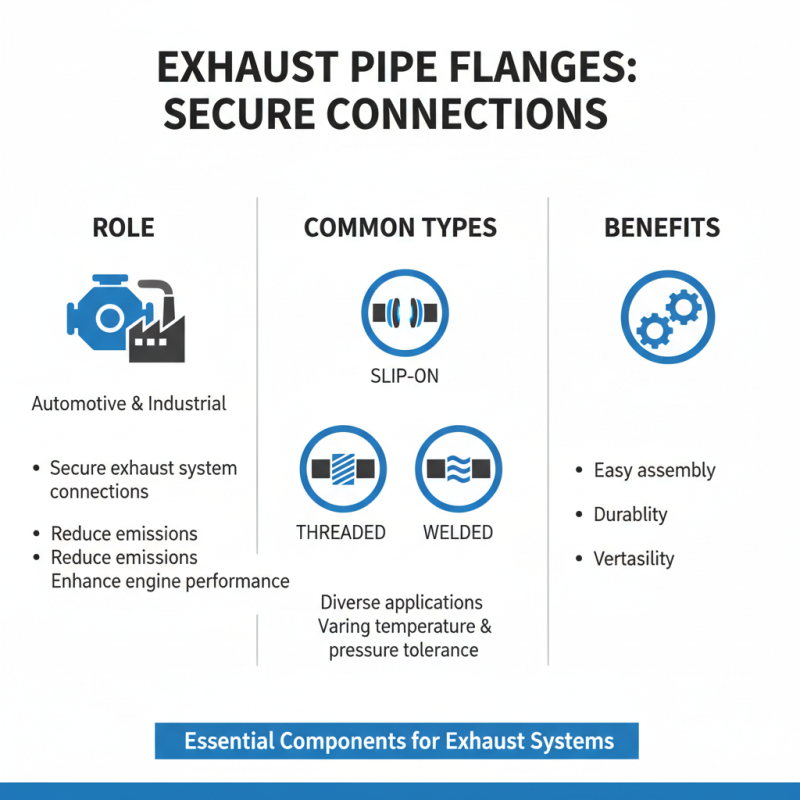

Exhaust Pipe Flange Types: An Overview of Common Designs in 2025

Exhaust pipe flanges play a critical role in ensuring secure connections in automotive exhaust systems. In 2025, several common flange designs have emerged, each tailored to specific application needs. The most widely used types include the flat flange, the slip-on flange, and the raised face flange. Flat flanges, characterized by their simple and even surfaces, provide a dependable seal and are commonly found in various exhaust setups. On the other hand, slip-on flanges are designed for ease of installation and flexibility, making them suitable for systems that require regular maintenance or adjustments.

Another notable design is the raised face flange, which offers enhanced sealing capabilities by providing a slight elevation at the joint interface. This feature ensures a tighter fit and minimizes the risk of leaks, particularly in high-temperature applications. Understanding these flange types not only helps in selecting the appropriate components for exhaust systems but also aids in troubleshooting and optimizing performance. Consequently, equipping oneself with knowledge about these common exhaust pipe flange designs is essential for automotive professionals and enthusiasts alike in 2025.

Key Material Considerations for Exhaust Pipe Flanges: A Technical Analysis

When selecting materials for exhaust pipe flanges, the analysis of thermal resistance and corrosion potential is crucial. According to a report by the International Journal of Materials Science, stainless steel, particularly type 304 and 316, is widely favored for its excellent resistance to high temperatures and oxidation. These materials maintain structural integrity in environments that often exceed 900°C (1652°F). This durability makes them suitable for automotive and industrial applications, where exhaust systems face extreme conditions.

Furthermore, advancements in metallurgical engineering have led to the development of specialized alloys that significantly enhance performance. The use of titanium and Inconel alloys provides superior strength-to-weight ratios and exceptional resistance to thermal fatigue, as noted in a study published by the Society of Automotive Engineers (SAE). Such materials can effectively withstand the harsh environments of modern turbocharged engines, which are becoming increasingly prevalent since they experience higher pressures and temperatures. With the automotive industry projected to integrate these advanced materials in 40% of new vehicle designs by 2025, understanding the right material for exhaust pipe flanges will remain pivotal in ensuring performance and longevity.

Exhaust Pipe Flange Types and Their Applications in 2025

Applications of Exhaust Pipe Flanges in Automotive and Industrial Sectors

Exhaust pipe flanges play a crucial role in the automotive and industrial sectors, serving as essential components that ensure secure connections between exhaust pipes and other exhaust system parts. In the automotive industry, flanges are commonly used to facilitate the assembly of exhaust systems, helping to reduce emissions and enhance engine performance. Various types of flanges, such as slip-on, threaded, and welded varieties, provide specific benefits for different applications, accommodating diverse temperature and pressure conditions.

In the industrial sector, exhaust pipe flanges contribute significantly to the efficiency of manufacturing processes. They are essential in the construction of exhaust systems for industrial machinery, ensuring proper ventilation and emission control. The compatibility of flanges with different materials, such as stainless steel and aluminum, allows for their use in various applications, including power generation and chemical processing.

**Tips:** When selecting an exhaust pipe flange, consider factors such as material compatibility and specific application requirements. Regular inspection of flanges for wear and damage can prevent leaks and enhance system reliability. Additionally, ensure proper installation techniques to maintain the integrity and performance of the exhaust system.

Industry Standards and Specifications for Exhaust Pipe Flange Design

When it comes to the design and application of exhaust pipe flanges, industry standards and specifications play a crucial role in ensuring performance and safety. In 2025, advancements in materials and engineering practices are expected to refine these standards further, leading to more efficient exhaust systems in various applications, including automotive, aerospace, and industrial sectors. These flanges must meet stringent criteria for strength, temperature resistance, and compatibility with different exhaust configurations, thereby influencing their design processes.

Additionally, the aerospace industry faces unique challenges when it comes to exhaust systems, similar to issues encountered in the development of autoclaves for aerospace applications. The Council of Scientific and Industrial Research National Aerospace Laboratories (CSIR-NAL) in India is focused on addressing these challenges, emphasizing the need for innovative materials and fabrication techniques. As industry standards evolve, the integration of new technologies will be vital in enhancing the reliability and performance of exhaust pipe flanges, ensuring they meet the increasing demands of modern applications.

Ultimate Guide to Exhaust Pipe Flange Types and Applications in 2025

| Flange Type |

Material |

Application |

Industry Standards |

Size Range (inches) |

| Flat Flange |

Stainless Steel |

Automotive Exhaust Systems |

ASTM F1498 |

2-6 |

| Slip-On Flange |

Aluminum |

Heavy-Duty Trucks |

ISO 9001 |

3-8 |

| Bolt-On Flange |

Carbon Steel |

Motorcycle Exhaust |

SAE J2295 |

1.5-5 |

| Welded Flange |

Mild Steel |

Industrial Applications |

ANSI B16.5 |

2-10 |

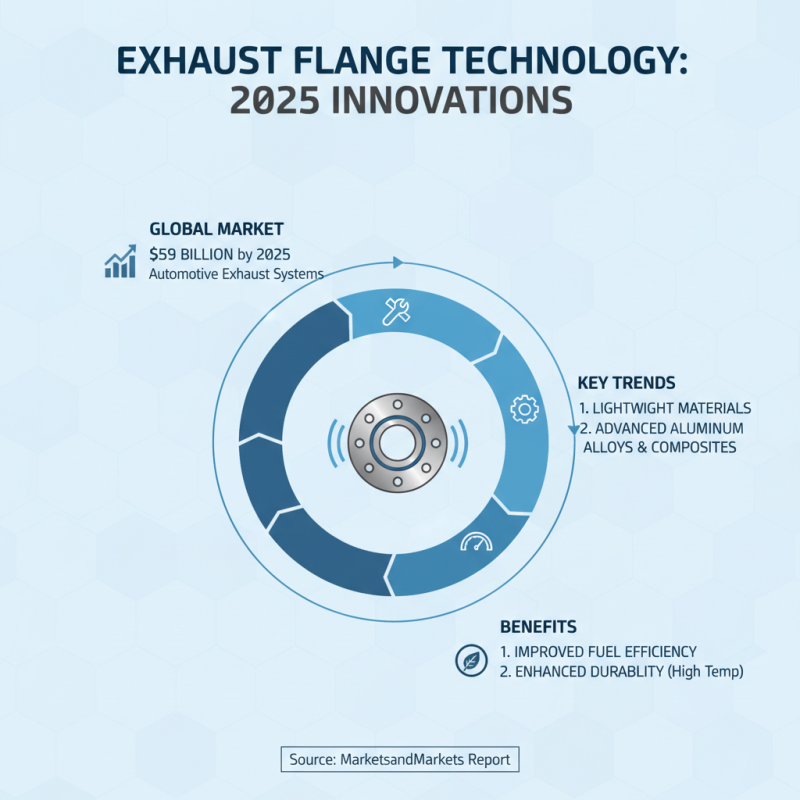

Future Trends and Innovations in Exhaust Flange Technology Through 2025

In the ever-evolving landscape of exhaust flange technology, innovations are poised to redefine industry standards by 2025. A recent report by MarketsandMarkets predicts the global automotive exhaust system market will reach $59 billion by 2025, underscoring the growing importance of efficient exhaust solutions. Among the emerging trends, the shift towards lightweight materials like composites and advanced aluminum alloys is notable. These materials not only reduce vehicle weight, thus improving fuel efficiency, but also enhance the durability of exhaust components under high-temperature conditions.

Furthermore, as emissions regulations become increasingly stringent worldwide, manufacturers are investing in smarter, more adaptable flange designs. For instance, modular flange systems that allow for easy integration with various exhaust configurations are gaining traction. According to a 2023 report by Allied Market Research, the demand for modular exhaust systems is expected to grow at a CAGR of 4.2% over the next few years. This flexibility enables automakers to better comply with diverse emission standards while catering to consumer preferences for customization, marking a significant shift towards more sustainable automotive practices and innovations in exhaust flange technology.

+86 17870576410

+86 17870576410

Home

Company Profile

Products

News

Blog

Contact Us

Contact Number

Contact Number