Top 10 Exhaust Pipe Flange Types You Need to Know for Your Vehicle

When it comes to your vehicle's exhaust system, the importance of the exhaust pipe flange cannot be overstated. This seemingly small component plays a vital role in ensuring the proper alignment and connection of exhaust pipes, which is crucial for optimal performance and efficiency. Over time, different types of exhaust pipe flanges have been developed to cater to a variety of vehicle models and applications. Understanding these various flange types can significantly enhance your ability to maintain and repair your vehicle's exhaust system.

In this guide, we will explore the top 10 exhaust pipe flange types that every vehicle owner should be aware of. From standard designs to specialized variations, each type serves a unique purpose in the exhaust assembly. Whether you're a seasoned mechanic or a car enthusiast, knowing the differences among these flanges will help you make informed decisions when it comes to upgrades, repairs, or replacements. Join us as we delve into the intricacies of exhaust pipe flanges and their essential role in keeping your vehicle running smoothly.

Overview of Exhaust Pipe Flanges and Their Importance

Exhaust pipe flanges play a crucial role in the performance and efficiency of a vehicle's exhaust system. These flanges are essential components that connect different sections of the exhaust system securely, ensuring that exhaust gases flow smoothly from the engine to the atmosphere. Their design can significantly impact how well the system operates, affecting everything from noise levels to overall emissions. Without properly functioning flanges, leaks can occur, leading to decreased performance and potential engine complications.

Understanding the various types of exhaust pipe flanges is important for vehicle maintenance and repair. Different flanges are designed to accommodate specific exhaust configurations and sizes, which can vary significantly across models and makes. This diversity means that having a comprehensive knowledge of the different types of flanges, including their shapes and materials, is vital for mechanics and DIY enthusiasts alike. Proper selection and installation of these flanges contribute to improved exhaust flow and reduced back pressure, ultimately enhancing the vehicle’s efficiency and lifespan.

Top 10 Exhaust Pipe Flange Types

This bar chart displays the distribution of various exhaust pipe flange types commonly found in vehicles. Understanding these types can assist in making informed decisions regarding maintenance and upgrades.

Common Types of Exhaust Pipe Flanges Used in Vehicles

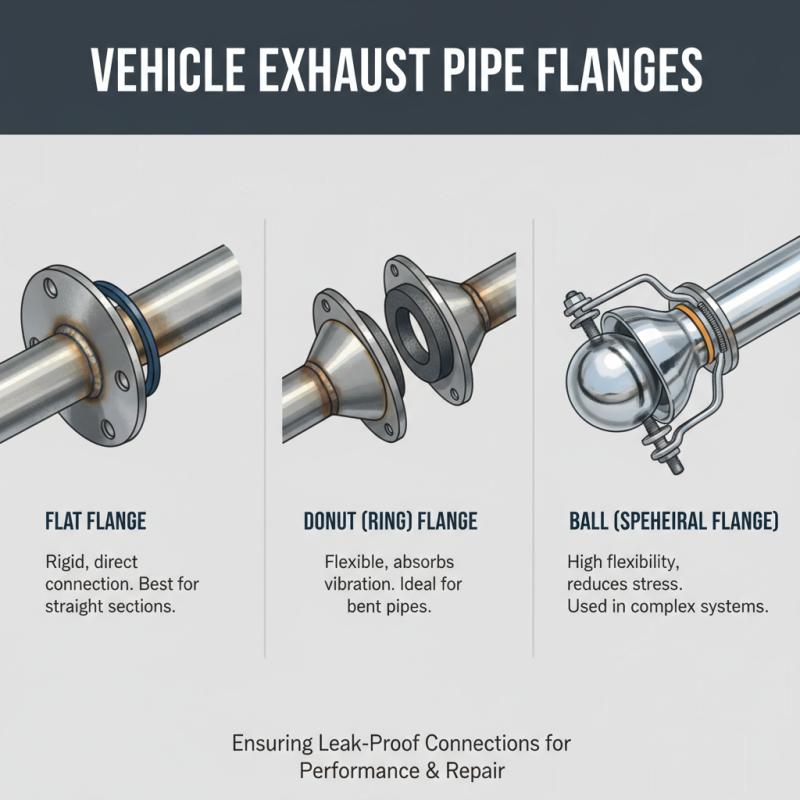

When it comes to vehicle exhaust systems, understanding the different types of exhaust pipe flanges is crucial for both repair and modification purposes. Flanges serve as vital connecting components that ensure a leak-proof seal between various sections of the exhaust system. Among the most common types are the flat flange, donut flange, and ball flange. Each of these has unique specifications tailored to fit particular exhaust designs, catering to different performance needs.

Industry reports indicate that the flat flange is predominantly used in a wide range of vehicles due to its straightforward design and ease of installation. It typically features a simple circular shape with bolt holes around the perimeter, allowing for secure fastening. Conversely, the donut flange, which resembles a thick ring, is often utilized in applications where flexibility is needed, as its design accommodates slight misalignments in the exhaust system. The ball flange, on the other hand, is favored for aftermarket applications due to its ability to provide a more adaptable joint that can accommodate thermal expansion and vibrations, essential for maintaining exhaust integrity during operation.

Understanding these different flange types is essential, especially considering that connecting parts in exhaust systems must undergo high temperatures and pressure fluctuations. According to the Automotive Engineering Association, the proper selection of exhaust flanges can significantly impact performance and durability, ultimately prolonging the life of the exhaust system while reducing emissions.

Detailed Examination of Each Top Exhaust Flange Type

When it comes to exhaust systems, the flange type used can significantly impact both performance and ease of installation.

Different vehicles require various flange configurations to ensure proper sealing and alignment of the exhaust piping.

Common types include flat flanges, which provide a simple and effective sealing surface for standard applications,

and donut flanges, characterized by their circular shape designed to accommodate flexibility in the exhaust system.

Both of these designs help reduce leakage and maintain optimal exhaust flow, but their specific applications can vary widely based on vehicle design and exhaust layout.

Another crucial flange type is the slip-on flange, commonly employed in custom exhaust setups.

This type allows for some degree of movement and adjustment, which can be particularly useful in high-performance modifications.

It relies on a slip joint that ensures a tight fit while enabling easy disassembly.

Additionally, the ball flange, often found in modern exhaust systems, features a spherical shape that allows for greater flexibility and movement,

helping to alleviate stress on exhaust components during vehicle operation.

Understanding these diverse flange types equips vehicle owners and enthusiasts with the knowledge to make informed decisions regarding exhaust repairs and modifications, ensuring better reliability and performance on the road.

Comparison of Flange Materials and Their Benefits

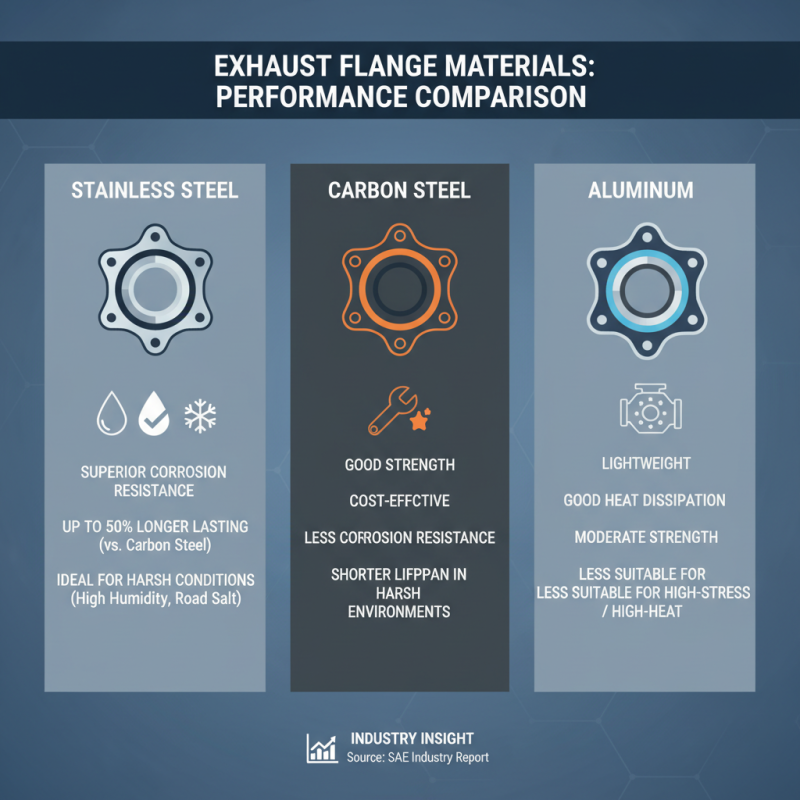

When it comes to exhaust pipe flanges, the choice of material can greatly impact performance, durability, and resistance to environmental factors. Common flange materials include stainless steel, carbon steel, and aluminum, each offering distinct advantages. According to a recent industry report by the Society of Automotive Engineers (SAE), stainless steel flanges demonstrate superior corrosion resistance, lasting up to 50% longer in harsh conditions compared to their carbon steel counterparts. This durability is particularly crucial in vehicles operating in regions with high humidity or frequent exposure to road salt.

In terms of weight, aluminum flanges are a popular choice for performance-oriented applications. Weighing roughly 40% less than stainless steel, aluminum flanges contribute to an overall reduction in vehicle weight, enhancing fuel efficiency and handling. However, the trade-off comes in the form of lower strength and heat resistance, making carbon and stainless steel flanges more suitable for heavy-duty applications. The Automotive Engineering Journal highlights that while aluminum may reduce initial costs, the longevity and strength of carbon and stainless steel options often provide a better return on investment over time, especially in demanding driving conditions. Understanding these material properties is essential for vehicle owners and automotive professionals when selecting the right flange type for specific applications.

Maintenance Tips for Exhaust Pipe Flanges and Seals

Proper maintenance of exhaust pipe flanges and seals is crucial to ensure optimal performance and longevity of your vehicle's exhaust system. Regular inspections can help detect any signs of wear or damage, which, if left unaddressed, can lead to leaks and decreased efficiency. Pay close attention to the condition of the flanges themselves, ensuring they are free from rust, cracks, or deformities that may affect their ability to create a proper seal. Additionally, evaluating the seals for deterioration, such as cracking or missing segments, is vital to prevent exhaust gases from escaping.

To maintain the integrity of your exhaust system, consider applying a high-temperature silicone sealant during assembly. This can enhance the sealing capability and provide extra protection against extreme conditions. Furthermore, it’s beneficial to periodically tighten the bolts and nuts that secure the flanges, as they can become loose over time due to vibrations and thermal expansion.

Using a torque wrench for this task ensures that the correct tension is applied, reducing the risk of over-tightening, which can also compromise the flanges. Being proactive in these maintenance practices will not only enhance your vehicle's performance but also extend the life of your exhaust system.

+86 17870576410

+86 17870576410

Home

Company Profile

Products

News

Blog

Contact Us

Contact Number

Contact Number