The Ultimate Guide to Understanding Exhaust Valve Function and Maintenance

Understanding the function and maintenance of the exhaust valve is crucial for anyone looking to optimize engine performance and longevity. The exhaust valve plays a vital role in the internal combustion process, allowing spent gases to exit the combustion chamber and maintaining optimal pressure within the engine. Yet, many vehicle owners overlook the importance of this component until issues arise, resulting in decreased efficiency or even catastrophic engine failure. This guide aims to demystify the intricacies of exhaust valve operation, explore common types and functions, and provide essential maintenance tips to ensure this critical component remains in peak condition.

Whether you are a car enthusiast or a casual driver, recognizing the significance of the exhaust valve will empower you to take better care of your vehicle, enhancing both its performance and reliability over time.

Understanding Exhaust Valve Types: Key Features and Performance Metrics

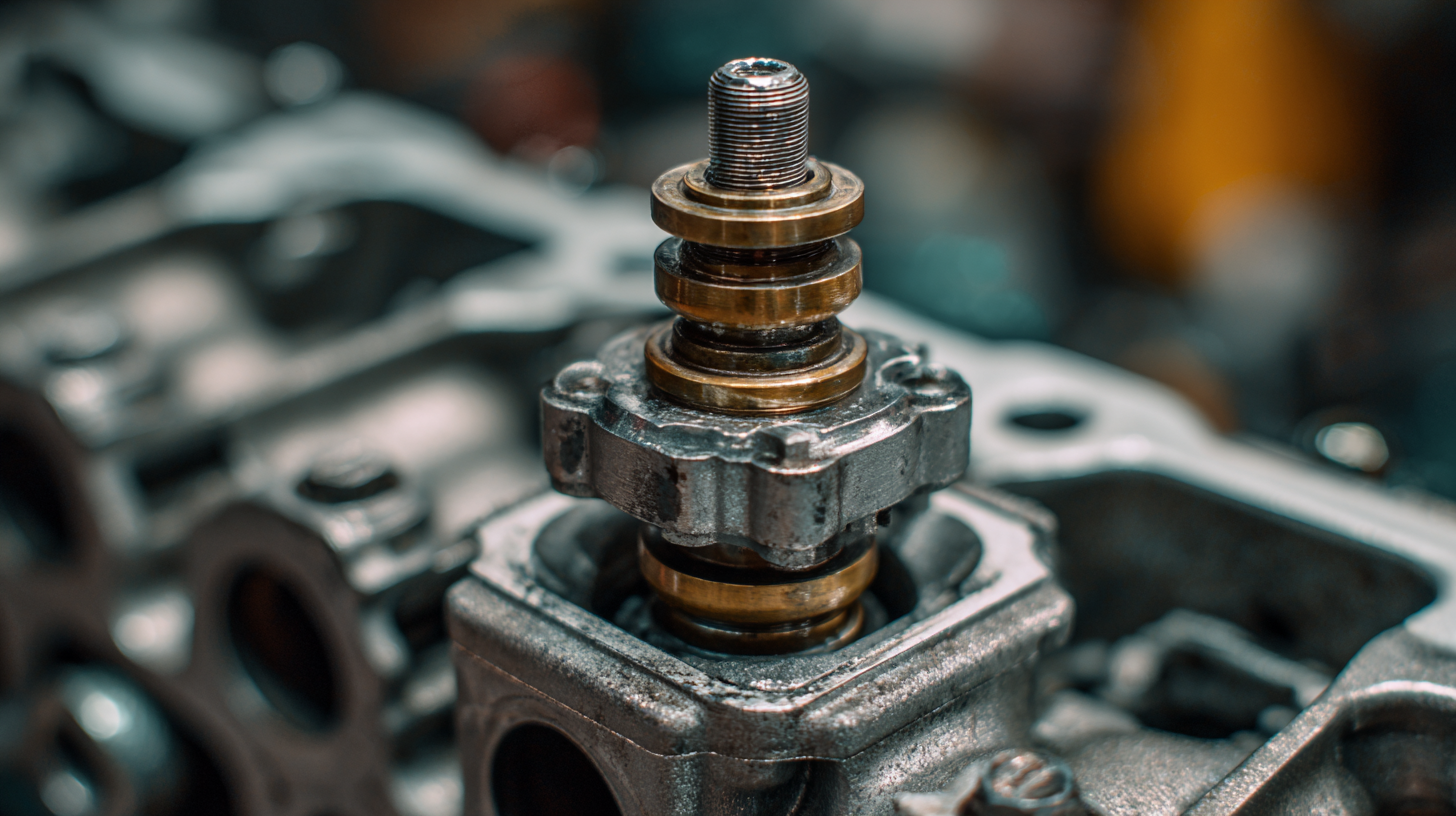

Exhaust valves play a critical role in vehicle performance, controlling the expulsion of exhaust gases from the combustion chamber. There are several types of exhaust valves, each featuring distinct characteristics that influence engine efficiency and power output. For instance, poppet valves are among the most common due to their simplicity and effectiveness in sealing combustion chambers. Meanwhile, more advanced options like sodium-filled valves provide enhanced thermal conductivity, allowing for improved heat dissipation in high-performance engines.

Performance metrics are essential when evaluating different exhaust valve types. Factors such as flow rate, durability, and resistance to heat are vital in determining how well an exhaust valve will perform under various conditions. High-flow valves are designed to minimize backpressure, promoting better engine breathing and power. Additionally, the materials used in valve construction, such as stainless steel or titanium alloys, greatly affect both performance and longevity. Understanding these key features not only aids in selecting the right exhaust valve for specific applications but also contributes to effective maintenance strategies that can prolong engine life and efficiency.

The Role of Exhaust Valves in Engine Efficiency: Industry Insights and Statistics

Exhaust valves play a critical role in engine efficiency, acting as the gatekeepers for the expulsion of exhaust gases after combustion. When an engine operates, the combustion process generates high-pressure gases that need to exit the cylinder effectively to maintain optimal performance. The precise timing and functioning of exhaust valves directly influence the engine's ability to breathe, which in turn affects power output, fuel consumption, and overall emissions. Research indicates that well-maintained exhaust valves can improve engine efficiency by as much as 5-10%, showcasing their significance in modern engine design.

Industry statistics reveal that inadequate exhaust valve maintenance is a leading cause of reduced engine performance and increased operational costs. Regular inspections and timely replacement of worn-out valves can prevent significant issues such as overheating, loss of power, and increased fuel consumption. Furthermore, advancements in valve technology, including variable valve timing systems, have been shown to enhance engine responsiveness and efficiency even further. Understanding the critical role of exhaust valves not only helps manufacturers design better engines but also enables vehicle owners to make informed decisions regarding maintenance practices that will prolong engine life and improve overall performance.

Common Exhaust Valve Issues: Symptoms, Causes, and Preventive Strategies

Exhaust valves are crucial components in an engine, and understanding common issues related to them can enhance engine performance and longevity. Symptoms of faulty exhaust valves include decreased engine power, unusual sounds, and increased exhaust smoke. According to a recent report by the Society of Automotive Engineers (SAE), approximately 15% of engine failures are attributed to exhaust valve problems, highlighting the importance of regular checks.

The primary causes of these issues often stem from excessive heat, wear and tear, or improper installation. High temperatures can lead to valve warping, while inadequate lubrication may cause erosion. Preventive strategies include routine maintenance, such as checking the valve clearances and using high-quality engine lubricants. A study by the Engine Manufacturers Association (EMA) found that 30% of valve failures could be prevented through consistent maintenance practices. Regular inspections and early detection of symptoms are essential to mitigate expensive repairs and prolonged downtime.

Maintenance Tips for Exhaust Valves: Best Practices and Frequency Recommendations

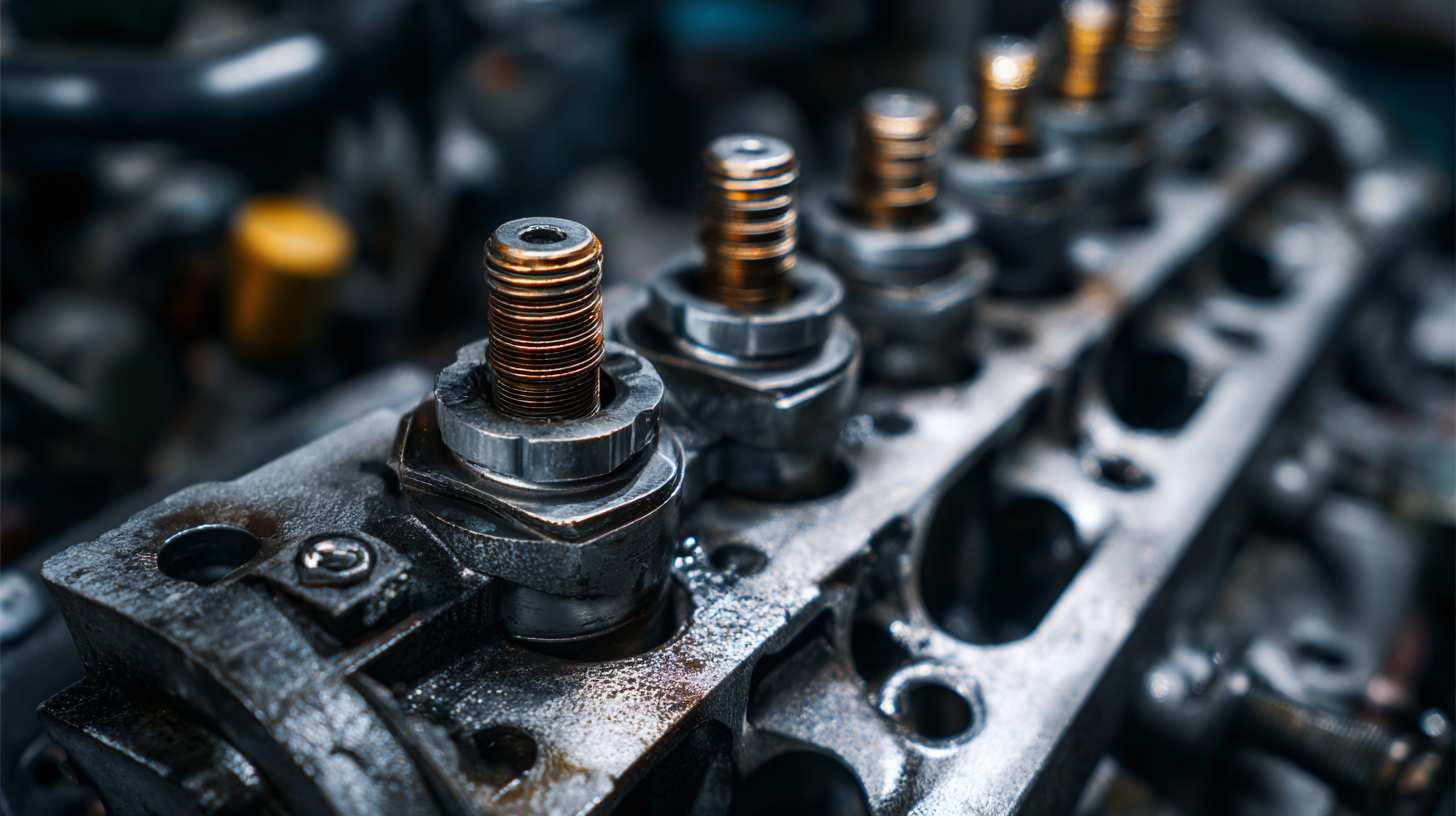

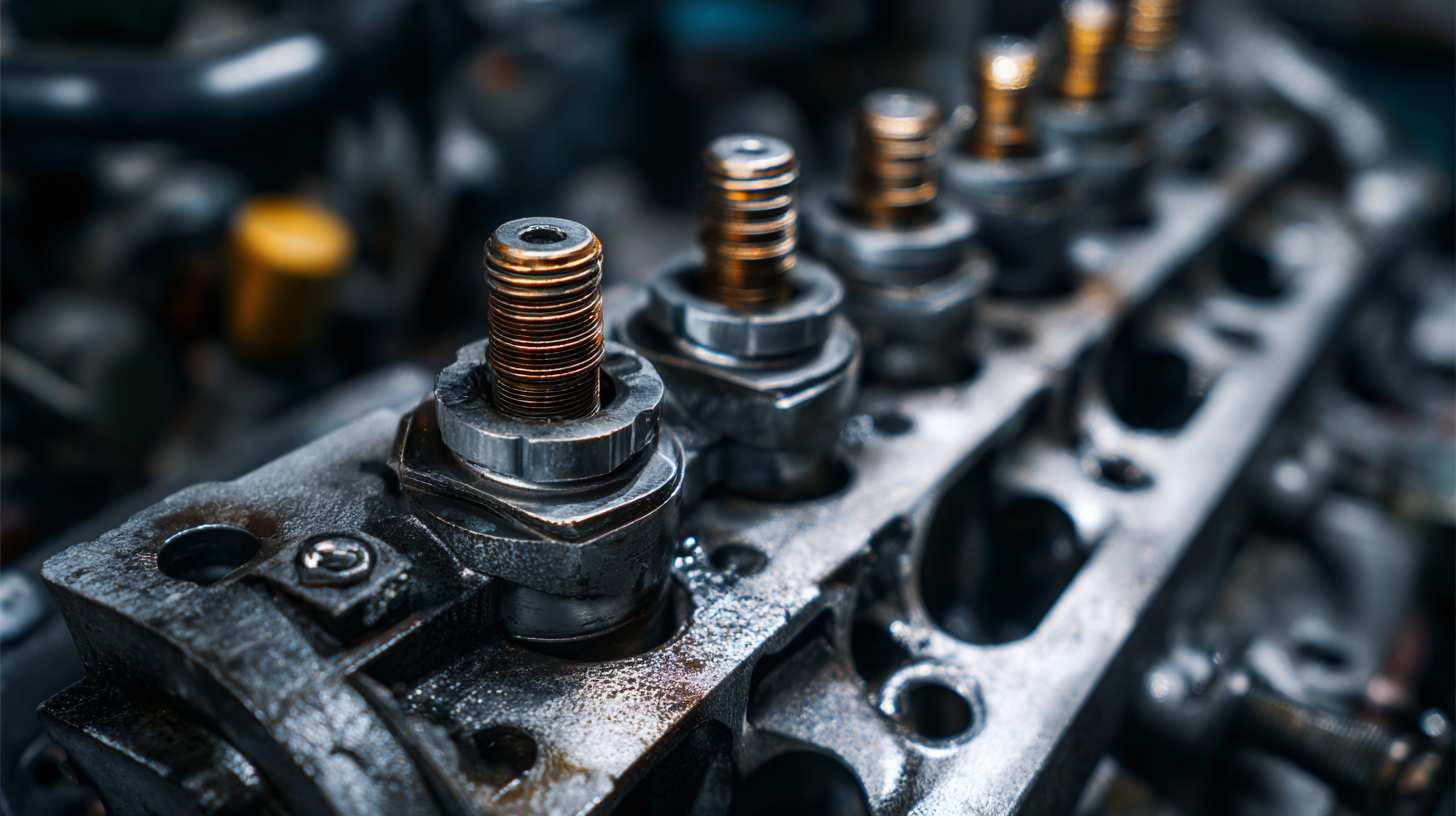

Maintaining exhaust valves is crucial for ensuring optimal engine performance and longevity. Regular inspection is key; it is recommended to check exhaust valves every 10,000 miles or as specified in your vehicle's service manual. During these inspections, look for signs of wear, carbon buildup, or any damage that could affect their functioning. If you notice irregularities, consider performing a thorough cleaning or replacing the valves to prevent more significant issues down the line.

In addition to regular checks, proper lubrication is essential for exhaust valves to function smoothly. Use high-quality engine oil and follow the manufacturer's recommendations for oil changes to ensure that the valves remain well-lubricated. It's also important to pay attention to valve clearance. Adjusting the clearance according to specifications helps maintain engine efficiency and reduces the risk of valve-related problems. By following these maintenance tips, you can enhance the reliability of your vehicle's exhaust system and improve overall engine performance.

Innovative Technologies in Exhaust Valve Design: Enhancements and Future Trends

Innovative technologies in exhaust valve design have significantly transformed engine performance and efficiency. Modern exhaust valves are now being crafted from advanced materials such as titanium and special alloys that offer superior heat resistance and lower weight. These materials not only enhance the durability of the valves but also optimize their response times, allowing for improved engine performance under various operational conditions. Additionally, innovations like variable valve timing (VVT) systems allow for better control over the exhaust flow, resulting in increased fuel efficiency and reduced emissions.

Future trends in exhaust valve technology point towards the integration of smart features that monitor valve performance in real-time. This would enable more adaptive and responsive control systems that adjust operations based on engine demands, ultimately resulting in better overall engine management. Furthermore, the adoption of 3D printing in manufacturing exhaust valves holds promise for creating complex designs that can lead to reductions in weight and increases in efficiency. As research and development in these areas continue, the implications for automotive performance, sustainability, and environmental impact appear to be profound.

The Ultimate Guide to Understanding Exhaust Valve Function and Maintenance - Innovative Technologies in Exhaust Valve Design: Enhancements and Future Trends

| Dimension |

Specification |

Maintenance Guidelines |

Innovative Features |

Future Trends |

| Material |

Stainless Steel |

Regular inspections for corrosion |

Heat resistance coatings |

Smart materials with self-healing properties |

| Diameter |

30 mm |

Adjust valve clearance as needed |

Variable diameter design |

3D printed valves for custom applications |

| Sealing Performance |

High integrity sealing |

Check for leaks annually |

Advanced sealing materials |

Integration with IoT for monitoring |

| Lifespan |

100,000 miles |

Replacement if performance drops |

New alloys for longer life |

Usage of machine learning to predict failures |

| Operating Temperature |

Up to 800°C |

Regular thermal stress checks |

Cooling technologies to reduce heat |

Nanotechnology for thermal management |

+86 17870576410

+86 17870576410

Home

Company Profile

Products

News

Blog

Contact Us

Contact Number

Contact Number