What is Flexible Exhaust Tubing and How Does It Work?

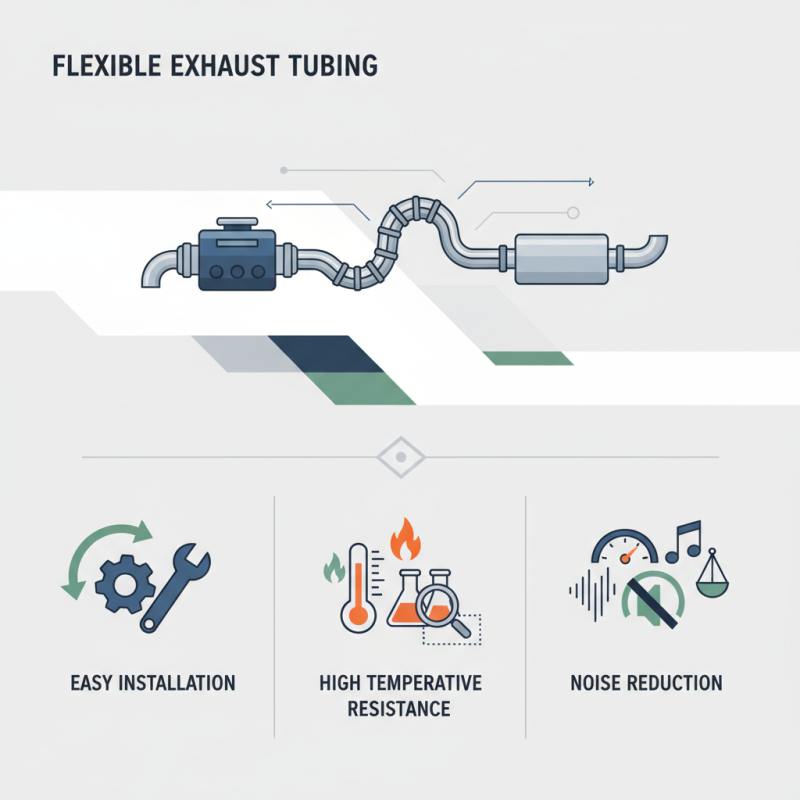

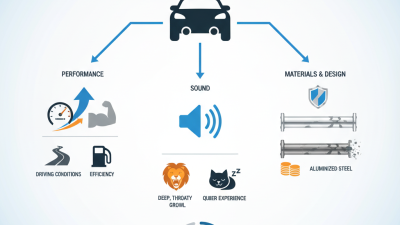

Flexible Exhaust Tubing is an innovative solution for modern vehicles. It allows for easier exhaust management and efficient engine performance. This type of tubing is designed to withstand high temperatures and corrosive gases.

The flexibility of the tubing makes installation straightforward. Mechanics can navigate complex layouts easily. For car enthusiasts, this means enhancing their tuning options. However, the durability can sometimes be a concern. Drivers should regularly check for wear and tear.

Flexible Exhaust Tubing also provides sound dampening benefits. It helps create a smoother exhaust flow, reducing unwanted noise. While many enjoy the quieter ride, some may miss the thrilling engine roar. Thus, it's essential to find a balance between noise and comfort.

Definition and Composition of Flexible Exhaust Tubing

Flexible exhaust tubing is a versatile component widely used in various automotive and industrial applications. It is primarily composed of a series of materials such as stainless steel, rubber, or other heat-resistant polymers, which allow it to withstand high temperatures and corrosive exhaust gases. This tubing can easily bend and twist, making installation in cramped spaces much simpler.

The unique composition of flexible exhaust tubing allows it to absorb vibrations and movement from the engine. This feature reduces the risk of damage to other components. The flexible nature also enables tighter configurations. However, not all installations benefit from these materials. Sometimes, improper installation leads to leaks or premature wear. It's crucial to ensure that the tubing is secured correctly and monitored regularly.

Moreover, flexible exhaust tubing typically has a mesh design that provides strength and flexibility simultaneously. This duality is helpful in adapting to engine shifts. Yet, this adaptability can occasionally result in stress points that might weaken over time. Regular inspections can help identify weak spots early. Understanding the material composition and function of flexible exhaust tubing is essential for optimal performance.

Understanding the Composition of Flexible Exhaust Tubing

Types of Flexible Exhaust Tubing and Their Applications

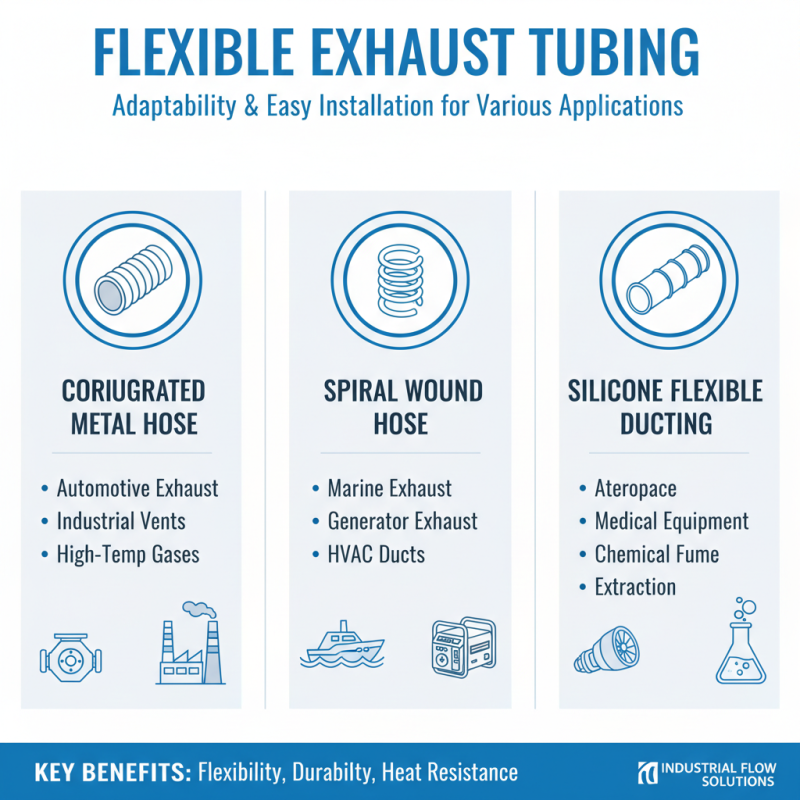

Flexible exhaust tubing is essential in various applications. It offers adaptability in tight spaces and easy installation. Here are a few types of flexible exhaust tubing and their uses.

One common type is the corrugated tubing. It can withstand high temperatures and resist corrosion. This makes it perfect for automotive exhaust systems. Its design allows for movement without leaking gases. Another type is the silicon tubing, often used in tuning applications. It’s flexible yet durable. This versatility aids in routing exhaust gases efficiently. However, it may not handle extreme heat as well as metal options.

In industrial settings, flexible exhaust tubing is vital for ventilation. It connects machinery to exhaust systems. This helps to remove harmful fumes. However, improper installation often reduces efficiency. Over time, some materials may degrade, leading to leaks. Regular inspection is crucial to maintain effectiveness.

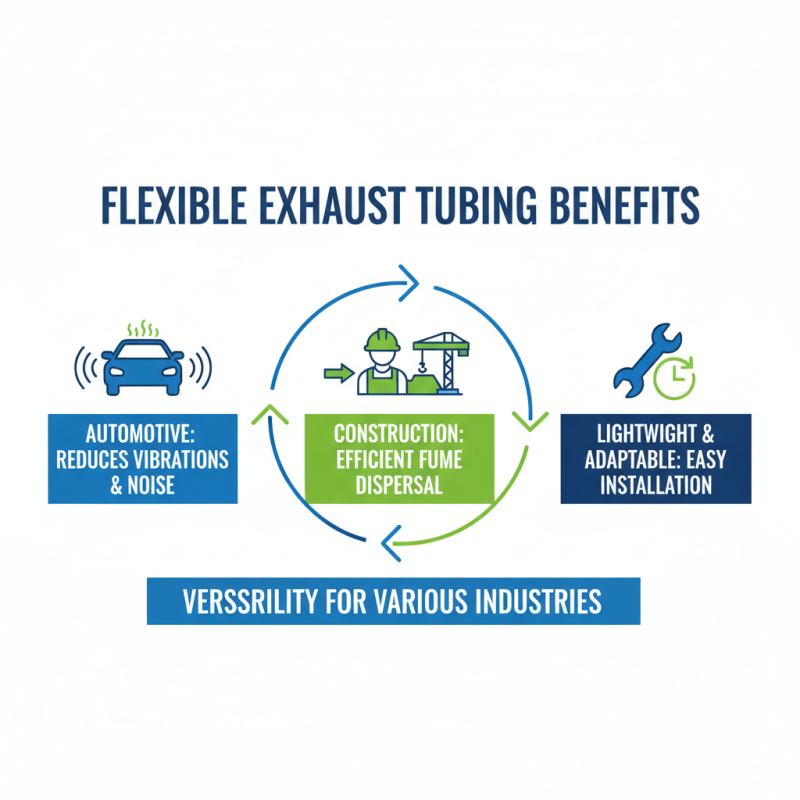

Benefits of Using Flexible Exhaust Tubing in Various Industries

Flexible exhaust tubing offers numerous benefits across various industries. Its adaptability makes it ideal for different applications. For instance, in automotive settings, it helps reduce vibrations and noise. In construction, it efficiently directs exhaust gases away from work areas. The lightweight nature of this tubing also simplifies installation and reduces labor costs.

**Tip:** When selecting flexible exhaust tubing, consider the material's temperature resistance. Different environments require specific ratings for optimal performance.

In manufacturing, flexible exhaust systems enhance safety. They prevent the buildup of harmful gases in enclosed spaces. Additionally, this tubing can be easily routed around obstacles, making it suitable for complex setups. Companies appreciate the ease of maintenance, as it can be replaced without significant downtime.

**Tip:** Regularly inspect your exhaust tubing for wear and tear. Early detection can save on costly repairs.

In some cases, flexible exhaust tubing may not fit perfectly. Adjustments might be needed during installation. This could lead to inefficiencies if not addressed. However, the overall benefits often outweigh these challenges, especially with proper attention to detail.

Installation Process and Best Practices for Flexible Exhaust Tubing

Flexible exhaust tubing is a popular choice for automotive and industrial applications. However, installation is crucial for optimal performance. Understanding the proper process can enhance efficiency and longevity.

Start with measuring the required length of tubing. Cut it accurately, as improper lengths can lead to leaks or excess strain. A tight connection is essential to minimize exhaust leakage. Using high-temperature resistant clamps can reinforce the joints. The installation area should be free from debris. This ensures a clean seal and maintains system integrity.

Tips: Always wear safety gear during installation. Protective gloves and goggles can prevent injuries. Also, check local regulations regarding exhaust systems.

Additionally, consider supporting the tubing during installation. Proper supports can prevent sagging or misalignment. A study by the Institute of Mechanical Engineering indicated that poorly installed exhaust systems can reduce efficiency by up to 15%. Lastly, inspect the tubing regularly. Look for signs of wear or cracking, as consistent checks can prevent more extensive damage.

Maintenance and Care Tips for Prolonging the Life of Flexible Exhaust Tubing

Flexible exhaust tubing is essential for many vehicles. Proper maintenance ensures a longer lifespan. Regular inspections will help you catch issues early. Look for cracks, leaks, or signs of wear. Also, check the connections to make sure they’re secure.

When cleaning flexible exhaust tubing, use a gentle cleanser. Harsh chemicals can damage the material. Rinse thoroughly to remove any residue. This step retains the tubing's flexibility and durability. Pay attention to areas around joints where debris may accumulate. They often need extra care.

Consider protective coatings to extend the tubing's life. These can shield against rust and corrosion. Keeping your exhaust system clean not only enhances performance but also reduces noise. Ensuring appropriate temperatures helps too. Overheating can lead to premature failure. Make these tips a regular part of your maintenance routine for better durability.

What is Flexible Exhaust Tubing and How Does It Work? - Maintenance and Care Tips for Prolonging the Life of Flexible Exhaust Tubing

| Aspect |

Description |

Maintenance Tips |

Lifespan |

| Material |

Typically made from stainless steel or high-temperature resistant materials, allowing flexibility and resistance to corrosion. |

Inspect regularly for any signs of wear or damage, cleaning to remove soot or debris buildup. |

5-10 years, depending on usage and environmental conditions. |

| Function |

Facilitates the safe exit of exhaust gases while allowing for some movement and vibration. |

Ensure proper installation to minimize stress and potential leaks in the joints. |

Varies with installation and maintenance; affected by exposure to extreme temperatures. |

| Installation |

Requires specific bends and configurations to accommodate vehicle design, often needing professional installation. |

Ensure connections are secure and use proper clamps to avoid leaks; check for alignment regularly. |

Influenced by installation quality and use patterns; regular checks can extend lifespan. |

| Common Issues |

Cracking, corrosion, and loosening of clamps can lead to exhaust leaks. |

Address any unusual noises or smells immediately; schedule routine inspections. |

If not maintained, issues can reduce lifespan to as little as 2-3 years. |

+86 17870576410

+86 17870576410

Home

Company Profile

Products

News

Blog

Contact Us

Contact Number

Contact Number